Nankai University-Rockwell Automation Intelligent Manufacturing Innovation Center

Introduction of the Center:

With the advent of information technology waves such as Industry 4.0 and Internet+, as well as “Made in China 2025 ”and the Belt and Road Initiative, universities are in urgent need of building knowledge and curriculum systems in the face of rapid technological changes, keeping pace with the times and building a bridge between teaching practices and industrial development. The course of Rockwell Automation Intelligent Manufacturing Innovation Center studies artificial intelligence in industry by adopting case-based and interdisciplinary teaching methods, so that students can understand industrial processes and master the principles of industrial automation. It has laid the foundation for the cross integration of disciplines such as automation, electronics, Internet of Things, engineering management, intelligent manufacturing and industrial Internet.

The course of Rockwell Automation Intelligent Manufacturing Innovation Center introduces the working principles of various programmable logic controllers, combined with real and diverse controlled objects such as small arm robots, ball screw-controlled objects, synchronous belt stepper motor-controlled objects, and three-axis writing machines. The controlled objects perform corresponding motion control, so that students can independently write controller programs to analyze and complete the controlled object's motion control process, and realize the construction of industrial automation control system. The practical system of industrial automation in the course focuses on solving technical problems in engineering applications, improving students’ ability to operate and solve practical problems with knowledge and skills.

The Intelligent Manufacturing Innovation Center can provide experimental equipment and venues for undergraduates who are interested in artificial intelligence, intelligent manufacturing, industrial automation, and robot control of the whole university instead of just students of the College of Artificial Intelligence.

Directions supported:

The Rockwell Automation Intelligent Manufacturing Innovation Center has equipment worth more than 18 million RMB, which can support Nankai University in the following directions:

● Create the characteristics of industrial intelligence

Improve the practical teaching ability of the artificial intelligence major and several new engineering majors

● Provide teaching and experimental bases for students

Provide support for the teachers and students of Nankai to carry out industrialized and innovative comprehensive experiments.

● Contribute to students' technological innovation and participation in competitions

National Undergraduate Automation System Application Competition;

National Undergraduate Industrial Design Competition

Existing courses:

Industrial Practice of Intelligent Automation(0612)

Practice of Intelligent Industrial Control System(0573)

After completing the practical course, students are expected to master the following knowledge and skills:

Goal 1: Have a deeper understanding of the concept and control process of intelligent electromechanical and industrial automation systems;

Goal 2: Be familiar with the basic principles of commonly used controlled objects such as small-arm robots, ball screw-controlled objects, synchronous belt stepper motor-controlled objects, and three-axis writing machine-controlled objects, and master their basic usage methods;

Goal 3: Deeply understand the architecture of industrial PLC-based control systems, master the basic principles of controllers and CCW-based programming control;

Goal 4: Be able to independently control the movement of various controlled objects;

Goal 5: Be able to improve students' skills in hands-on practice, problem analysis and system design, and encourage students to innovate independently and carry out open design experiments.

Fig 1. Nankai University-Rockwell Automation Intelligent Manufacturing Innovation Center

Fig 2. Simulated industrial production line

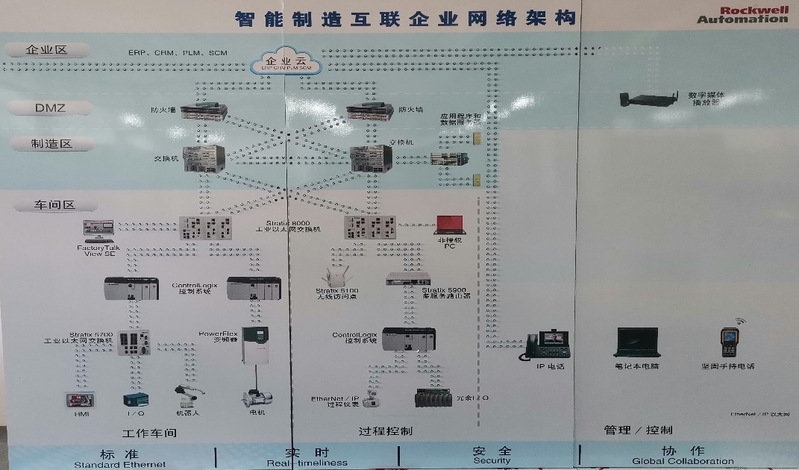

Fig 3. Intelligent manufacturing interconnected enterprise network architecture

Fig 4. Various controlled objects

Fig 5. Class presentation